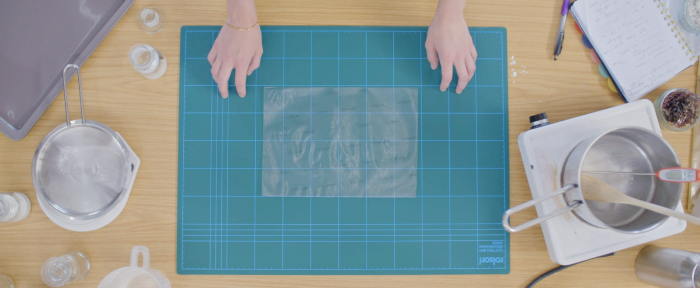

The fight against single-use plastic continues well-beyond 2020 and this marine bioplastic design – MarinaTex – wants to exchange plastic in food and drink packages with its own alternative made from fish waste.

Created by Lucy Hughes, 24, in 2018 for her final year undergraduate degree project, MarinaTex is the result of over 100 prototype tests conducted by Lucy over a kitchen stove from her student flat.

The see-through flexible sheet material, which also contains red algae, aims to solve the issue with over-consumption of plastic and find a sustainable way to re-use organic fish waste headed for the landfill.

MarinaTex is the winner of the 2019 International James Dyson award, which celebrates and challenges young engineering students and graduates ‘to design something that solves a problem’.

With the recent global wave of student climate change activism, which saw millions of young people protest for urgent action against climate change, Lucy’s biodegradable invention ‘represents the shift’ amongst students thinking about carbon footprints when inventing.

How useful is MarinaTex to the everyday person and why the interest in combating climate change?

The project began by addressing and utilising waste streams in the fishing industry. This then developed into creating a material that could help tackle our overconsumption of single-use plastic film, in some applications.

As a resident of Earth, this problem is hugely important to me. It’s not sustainable to create solutions that do not take into account all the parameters, footprint being one of them.

MarinaTex is unique for multiple reasons. Compared to its main competitor, conventional plastic, MarinaTex can fully biodegrade in home-food recycling bins or home composts without leaching chemicals into the environment.

At the moment it is most suited as a substitute to single-use plastic film, but I am undertaking further research and development this year to work out how else the material could be employed as the invention is still in its infancy.

Why did you choose fish waste out of all other forms of waste – including food waste?

I wanted to use a local waste stream as the basis of my invention. My university tutor at the time was working with a sustainable fishing plant who were looking for some alternative methods to recycle their offcuts.

Just looking at the fish skins and scales, I could see the potential locked up in these raw materials and just started experimenting!

Vision for MarinaTex – How much evolution did the idea go through up until its success?

From early on in the project, I was intent on creating a plastic alternative. However, as I’m not from a chemistry background it took a lot of self-teaching from open learning platforms and, crucially, a lot of trial and error.

At first, I looked at the shells, bones, blood and offal of the fish offcuts, but I finally settled on fish skins and scales bound with agar from red algae.

Can you point out major career decisions you have made throughout your life that has led you to the point of inventing MarinaTex?

MarinaTex is still in its infancy as an invention so I’m sure there are still many career milestones to come!

I have two major inspirations behind the project – The first being our over-dependency on plastic and the damage it has subsequently caused to the environment.

The second inspiration was learning about the principles of the circular economy, and how there is a viable system available that is restorative and regenerative by design.

This inspired me to value waste as a resource.

What has been your major challenges so far and how are you tackling them?

I’ve enjoyed so much of this whole process so far and I’m excited about what’s to come. Trying to teach myself the chemistry behind MarinaTex was a real challenge, but also incredibly rewarding.

Hopefully, it can inspire others to give sustainability and engineering a go, even if it isn’t their natural background.

How much of an impact do you foresee MarinaTex having now in the world and in the years to come?

Due to the nature of the project, MarinaTex is still in its infancy and it is not currently at the production stage.

The end goal is to bring the material to market and offer it as a viable alternative to single-use plastic films.

That said, this is just one potential usage of the material, and I look forward to undertaking more research and development to see how else the product could be employed.

The response from the packaging industry has been overwhelmingly positive. It’s encouraging to see suppliers looking for more sustainable packaging options across all sectors.

As a child, what did you see yourself becoming in the future? Does it have anything to do with where you are now?

I really had no idea of what I was going to become – I loved to rearrange my room, create elaborate fancy dress costumes, design houses on Sims and fix odd things around the house.

I now realise that this was a desire to create and an understanding of how products work and are integrated into our lives.

What would you tell your ten-year-old self?

Don’t change a thing, each challenge and triumph you face will add to your character. Always ask why, keep attention to detail and take pride in what you create.

Images Copyright – James Dyson Foundation

More Stories

The 10 Things You Need To Know About Building A Low-Carbon Startup

7 Important Lessons To Learn From Running A Health Tech Startup